05-15

AXIS COMPONENTS

2023-04-15

2023-04-15

The company adheres to the concept of design process collaboration and agile trial-production, and is based on the manufacturing of precision parts, applicable to: Aircraft, spacecraft, marine engines, small gas generators, compressors, and natural gas pipeline pressurization devices. It covers the machining of difficult-to-machine materials such as titanium alloy, aluminum-magnesium alloy, nickel-based superalloy and common steel materials. The precision is generally 0.01-0.02mm and part 0.005mm high precision and complex surface machining.

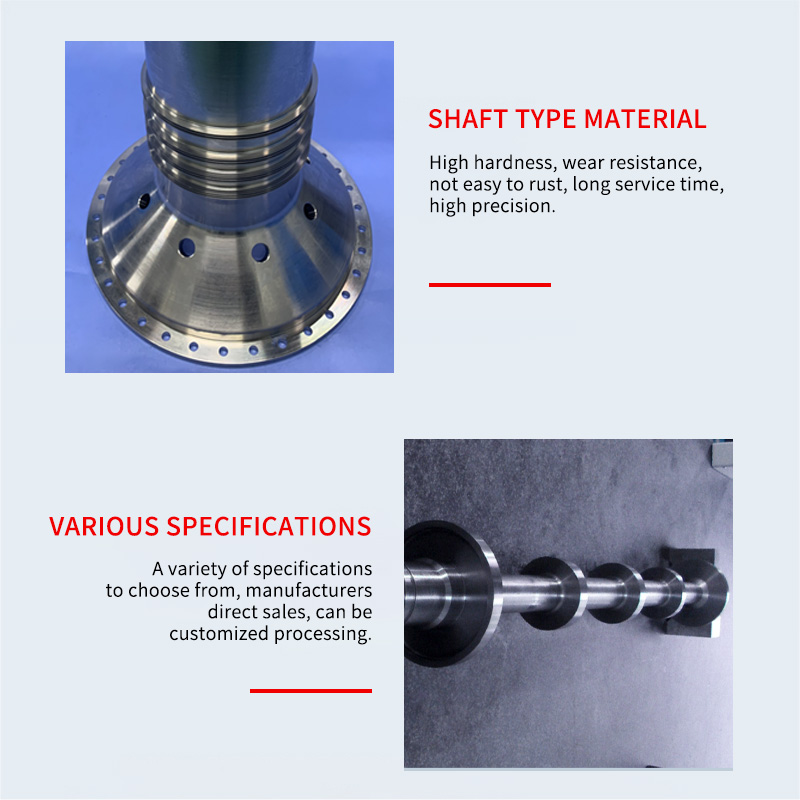

Shaft products include air guide shaft, transmission shaft, fan shaft, rear journal and low pressure turbine transmission shaft. The air duct shaft is a welded component, involving special processes such as electron beam welding, vacuum heat treatment, fluorescence inspection, x-ray inspection, spraying, dry film coating, dynamic balancing, etc. The material of the single piece is in718, the annular hollow cylindrical structure, the thinnest wall thickness is 2mm, the end faces on both sides are provided with end grooves, and the outer diameter is distributed with outer diameter grooves, mj threads and other characteristics. The requirements for coaxiality, runout and wall thickness difference are high. The transmission shaft is made of stainless steel, with a bottle-neck type inner hole shaft. The outer ends are distributed with thread and spline structure. The inner hole has a slope of 20 mm with a drop, multiple jumps, verticality and parallelism within 0.01 mm. The fan shaft is made of stainless steel hollow shaft with unilateral flange structure. The flange has installation holes, external distributed threads, radial holes and other features. The inner hole has 5h precision splines. The runout and cylindricity of the outer circle shall be within 0.01mm. The rear journal shaft is made of stainless steel, single-sided flange structure shaft, profile distribution sealing teeth, thread, inclined hole, end face structure, and 4h precision spline in the inner hole. The runout and cylindricity of multiple mating surfaces of the outer circle shall be within 0.01mm. The low pressure turbine drive shaft is made of stainless steel and solid multi-step structure shaft. Splines and threaded structures are distributed on the outside, and the middle part has multiple mounting flanges, mounting holes and other structures. Multiple runout and cylindricity are required to be within 0.02mm.

Shaanxi yinhan aerospace technology co., ltd. Was incorporated in june 2020. The registered capital of the company is 34.5 million yuan, which is invested by two legal person shareholders. At present, more than 35 million yuan has been invested mainly in fixed assets, and more than 20 million yuan has been invested in cash. There are 55 employees, including 11 technicians, 2 quality management personnel, 4 inspection personnel and 26 production personnel. The company adheres to the concept of design process coordination and agile trial production, based on the manufacturing of precision parts, and is committed to building a high-tech enterprise of civil gas turbine engine and compression device. The company has an existing workshop area of 2452 square meters, with 4 high-precision cnc machining centers, 13 cnc lathe processing equipment, and a total of 28 equipment, such as putzmai abrasive flow, wire cutting, piercing machine, universal mill, and general lathe. The company has 3 sets of inspection equipment, including hixconn explorer152210 cmm, and 151 sets of various inspection instruments. At present, the company has passed and obtained the gb/t19001-2016/iso9001:2015 quality management system certification, and has obtained the high-tech enterprise certification.

Suo Wentao

shichang@yhktkj.com

Disclaimer: This article is reproduced from other media. The purpose of reprinting is to convey more information. It does not mean that this website agrees with its views and is responsible for its authenticity, and does not bear any legal responsibility. All resources on this site are collected on the Internet. The purpose of sharing is for everyone's learning and reference only. If there is copyright or intellectual property infringement, please leave us a message.